Cutting Fluid For Semiconductor Equipment Manufacturing Market Size And Forecast

Cutting Fluid For Semiconductor Equipment Manufacturing Market size was valued at USD 77.78 Million in 2023 and is projected to reach USD 107.61 Million by 2031, growing at a CAGR of 4.18% from 2024 to 2031.

Rising demand for electronics and miniaturization and integration are the factors driving market growth. The Global Cutting Fluid For Semiconductor Equipment Manufacturing Market report provides a holistic evaluation of the market. The report offers a comprehensive analysis of key segments, trends, drivers, restraints, competitive landscape, and factors that are playing a substantial role in the market.

>>> Get | Download Sample Report @ – https://www.verifiedmarketresearch.com/download-sample/?rid=404365

Global Cutting Fluid For Semiconductor Equipment Manufacturing Executive Summary

The cutting fluid market in the semiconductor industry comprises a specialized sector dedicated to providing fluids and lubricants customized for the intricate machining processes involved in semiconductor equipment manufacturing. These fluids play a crucial role in optimizing operations such as milling, drilling, and grinding by facilitating cooling, lubrication, chip removal, and corrosion prevention. The market is characterized by an unwavering pursuit of precision and efficiency, as semiconductor manufacturers endeavor to meet stringent quality standards and keep pace with advancing technologies. Key drivers shaping this market include the relentless progress of semiconductor technology, which requires cutting fluids capable of handling increasingly complex materials such as silicon, gallium arsenide, and other compound semiconductors. As the industry pushes boundaries with smaller feature sizes and tighter tolerances, cutting fluids must demonstrate exceptional stability and performance under high-speed machining conditions, minimizing tool wear and surface defects.

Furthermore, environmental and health considerations exert a significant influence on market dynamics. Stringent regulations and industry standards drive the demand for cutting fluids with reduced environmental impact, characterized by low levels of volatile organic compounds (VOCs) and hazardous additives. Manufacturers are under pressure to develop formulations that are biodegradable, compatible with wastewater treatment processes, and aligned with sustainability goals. Each type of cutting fluid offers distinct advantages in terms of lubrication effectiveness, heat dissipation, and environmental compatibility, catering to the diverse needs of semiconductor equipment manufacturers. Ongoing research and development efforts drive innovation within the market, focusing on enhancing lubrication properties, extending tool life, and reducing the environmental footprint. Market players compete not only on product performance but also on factors such as reliability, compatibility with manufacturing processes, and cost-effectiveness.

The trend towards Industry 4.0 and smart manufacturing is a crucial driver accelerating the global cutting fluid market for semiconductor equipment manufacturing. Industry 4.0 represents the integration of digital technologies into manufacturing processes to create smart factories that are interconnected, data-driven, and highly automated. In the semiconductor industry, adopting Industry 4.0 principles has led to implementing advanced manufacturing technologies such as automation, robotics, the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. These technologies enable real-time monitoring, predictive maintenance, process optimization, and seamless integration across the semiconductor manufacturing value chain.

What's inside a VMR

industry report?

Our reports include actionable data and forward-looking analysis that help you craft pitches, create business plans, build presentations and write proposals.

Download Sample

>>> Ask For Discount @ – https://www.verifiedmarketresearch.com/ask-for-discount/?rid=404365

Global Cutting Fluid For Semiconductor Equipment Manufacturing Market Attractiveness Analysis

The above figure represents the bubble chart. It has been employed to depict market attractiveness by combining three data points: the X-axis and Y-axis, and the size of the bubbles. This visual representation helps identify markets with optimal characteristics, aiding strategic decision-making based on attractiveness criteria. Here, for each region, the bubble size represents the incremental value from the year 2024 to 2031. Cutting fluids are required to support production processes in the semiconductor equipment manufacturing market, which is driven by Asia Pacific’s fast industrialization and rising consumer demand for electronics. The region’s skilled labor pool and strong supply chain infrastructure, in addition to government programs supporting semiconductor production, further fuel the expansion of the cutting fluid market in Asia Pacific.

The cutting fluid demand is significantly increased by China’s semiconductor sector, a worldwide manufacturing powerhouse driven by government investments, technological improvements, and a booming consumer electronics market. Cutting fluid demand is fueled by Japan’s expertise in precise engineering and semiconductor technology, as well as by a robust industrial base, R&D activities, and an emphasis on quality and innovation. The Cutting fluids are in high demand in the semiconductor equipment production sector due to India’s fast rising electronics industry, government attempts to boost local manufacture, and the expanding markets for smartphones, automotive electronics, and Internet of Things devices.

Global Cutting Fluid For Semiconductor Equipment Manufacturing Market Outlook

The rising demand for electronics significantly influences the global cutting fluid market for semiconductor equipment manufacturing. As consumer electronics continue to permeate various aspects of daily life, from smartphones and laptops to smart appliances and automotive electronics, the semiconductor industry experiences a surge in demand for semiconductor chips. This increased demand necessitates the production of more semiconductor manufacturing equipment, including precision machinery fabricating semiconductor components. Cutting fluids play a crucial role in these machining processes by lubricating, cooling, and removing metal chips during milling, turning, drilling, and grinding operations.

The semiconductor sector is well known for being cyclical, experiencing robust demand intervals interspersed with low demand times. Several factors affect the cycles of the semiconductor industry, including technological advancements, economic factors, and geopolitical issues. The infamously cyclical semiconductor industry had a tough year in 2023, the seventh downturn since 1990, with sales predicted to be down 9.4% (to USD 520 billion) for the year. This cyclical nature of the semiconductor industry presents a notable restraint on the global cutting fluid market for semiconductor equipment manufacturing. Semiconductor manufacturing is innately cyclical, characterized by periodic fluctuations in demand influenced by technological advancements, macroeconomic conditions, and market saturation. During economic downturns or industry contractions, semiconductor manufacturers often scale back production and capital expenditures, reducing demand for semiconductor equipment and related materials, including cutting fluids. This cyclicality poses challenges for cutting fluid manufacturers as they must navigate fluctuating demand and revenue instability.

The trend towards advanced packaging technologies in the semiconductor industry is a significant driver propelling the global cutting fluid market for semiconductor equipment manufacturing. Advanced packaging technologies involve innovative methods for assembling and packaging semiconductor components, enabling higher levels of integration, improved performance, and enhanced functionality in electronic devices. These technologies include 3D integrated circuits (3D ICs) and system-in-package (Sip). As semiconductor manufacturers adopt these advanced packaging techniques to meet the evolving demands of emerging applications such as artificial intelligence, 5G communication, and the Internet of Things (IoT), the complexity and precision requirements of semiconductor equipment manufacturing processes increase significantly.

Global Cutting Fluid For Semiconductor Equipment Manufacturing Market: Segmentation Analysis

The Global Cutting Fluid For Semiconductor Equipment Manufacturing Market is segmented on the basis of Type, Application, Cutting Fluid Type, and Geography.

Cutting Fluid For Semiconductor Equipment Manufacturing Market, By Type

- Cooling

- Lubrication

To Get a Summarized Market Report By Type:- Download the Sample Report Now

Based on Type, The market is segmented into Cooling and Lubrication. Cooling accounted for the largest market share of 65.66% in 2023, and is projected to grow at the highest CAGR of 4.47% during the forecast period. Cutting fluid formulation innovations have resulted in the creation of cutting-edge cooling systems designed especially for the production of semiconductor equipment. These cutting fluids are made to satisfy the strict purity standards of the semiconductor sector and to provide exceptional heat dissipation capabilities. In order to improve cooling efficiency, manufacturers are concentrating on creating cutting fluids with optimal heat transfer and thermal conductivity properties.

Cutting Fluid For Semiconductor Equipment Manufacturing Market, By Application

- Drilling And Milling

- Grinding And Polishing

- Others (Sawing, Turning, etc.)

Based on Application, The market is segmented into Drilling And Milling, Grinding And Polishing, and Others (Sawing, Turning, etc.). Grinding and polishing accounted for the largest market share of 41.84% in 2023, and is projected to grow at the highest CAGR of 4.96% during the forecast period. Grinding and polishing represent foundational stages in semiconductor manufacturing, critical for attaining the necessary surface finishes and dimensional tolerances vital to device performance. The abrasive nature of these processes results in significant heat and friction, presenting challenges such as thermal damage, tool wear, and surface imperfections. Cutting fluids play a pivotal role in addressing these challenges by furnishing effective cooling, lubrication, and chip removal, thereby bolstering process stability and product quality.

Cutting Fluid For Semiconductor Equipment Manufacturing Market, By Cutting Fluid Type

- Synthetic

- Semi-Synthetic

- Soluble

- Neat-Cutting Oils

Based on Cutting Fluid Type, The market is segmented into Synthetic, Semi-Synthetic, Soluble, and Neat-Cutting Oils. Soluble accounted for the largest market share of 43.96% in 2023, with a market Value of USD 34.19 Million and is projected to grow at the highest CAGR of 5.02% during the forecast period. Semi Synthetics was the second-largest market in 2023, Value of USD 17.40 Million in 2023; it is projected to grow at a CAGR of 4.05%. Soluble cutting fluids act as coolant, dissipating heat from the machining zone and preventing thermal damage to both the work piece and the cutting tool. This is crucial for maintaining the integrity of delicate semiconductor materials and ensuring consistent manufacturing quality.

Cutting Fluid For Semiconductor Equipment Manufacturing Market, By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East And Africa

To Get a Summarized Market Report By Geography:- Download the Sample Report Now

Based on Geography, The Global Cutting Fluid For Semiconductor Equipment Manufacturing Market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East And Africa. Asia-Pacific accounted for the largest market share of 43.55% in 2023, and is projected to grow at the highest CAGR of 4.53% during the forecast period. Cutting fluids are required to support production processes in the semiconductor equipment manufacturing market, which is driven by Asia Pacific’s fast industrialization and rising consumer demand for electronics. The region’s skilled labor pool and strong supply chain infrastructure, in addition to government programs supporting semiconductor production, further fuel the expansion of the cutting fluid market in Asia Pacific. Cutting fluid demand is significantly increased by China’s semiconductor sector, a worldwide manufacturing powerhouse driven by government investments, technological improvements, and a booming consumer electronics market.

Key Players

The “Global Cutting Fluid For Semiconductor Equipment Manufacturing Market” is highly fragmented with the presence of a large number of players in the Market. Some of the major companies include Fuchs, Idemitsu Kosan, China Petroleum & Chemical Corporation, MORESCO Corporation, and 3X Polymer. This section provides company overview, ranking analysis, company regional and industry footprint, and ACE Matrix.

Our market analysis also entails a section solely dedicated for such major players wherein our analysts provide an insight to the financial statements of all the major players, along with its product benchmarking and SWOT analysis.

Company Market Ranking Analysis

The company ranking analysis provides a deeper understanding of the top 3 players operating Cutting Fluid For Semiconductor Equipment Manufacturing Market. VMR takes into consideration several factors before providing a company ranking. The top three players for the Cutting Fluid For Semiconductor Equipment Manufacturing Market include Idemitsu Kosan Co. Ltd., FUCHS, China Petrochemical Corporation. The factors considered for evaluating these players include company’s brand value, product portfolio (including product variations, specifications, features and price), company presence across major regions, product related sales obtained by the company in recent years and its share in the total revenue. VMR further study the company’s product portfolio based on the technologies adopted or new strategies undertaken by the company to enhance their market presence globally or regionally. We also consider the distribution network (online as well as offline) of the company that helps us to understand the company’s presence and foothold in various Cutting Fluid For Semiconductor Equipment Manufacturing Markets.

Company Regional/Industry Footprint

The company’s regional section provides geographical presence, regional level reach, or the respective company’s sales network presence. All the companies considered for profiling are reviewed similarly under this section. These sections help us to understand the overall Cutting Fluid For Semiconductor Equipment Manufacturing Market presence across globe.

Ace Matrix

This section of the report provides an overview of the company evaluation scenario in the Cutting Fluid For Semiconductor Equipment Manufacturing Market. The company evaluation has been carried out based on the outcomes of the qualitative and quantitative analyses of various factors such as the product portfolios, technological innovations, market presence, revenues of companies, and the opinions of primary respondents.

Report Scope

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| STUDY PERIOD | 2020-2031 |

| BASE YEAR | 2023 |

| FORECAST PERIOD | 2024-2031 |

| HISTORICAL PERIOD | 2020-2022 |

| Unit | Value (USD Million) |

| Key Companies Profiled | Fuchs, Idemitsu Kosan, China Petroleum & Chemical Corporation, MORESCO Corporation, and 3X Polymer. |

| Segments Covered | By Type, By Application, By Cutting Fluid Type, and By Geography. |

| Customization Scope | Free report customization (equivalent up to 4 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope. |

To Get Customized Report Scope:- Request For Customization Now

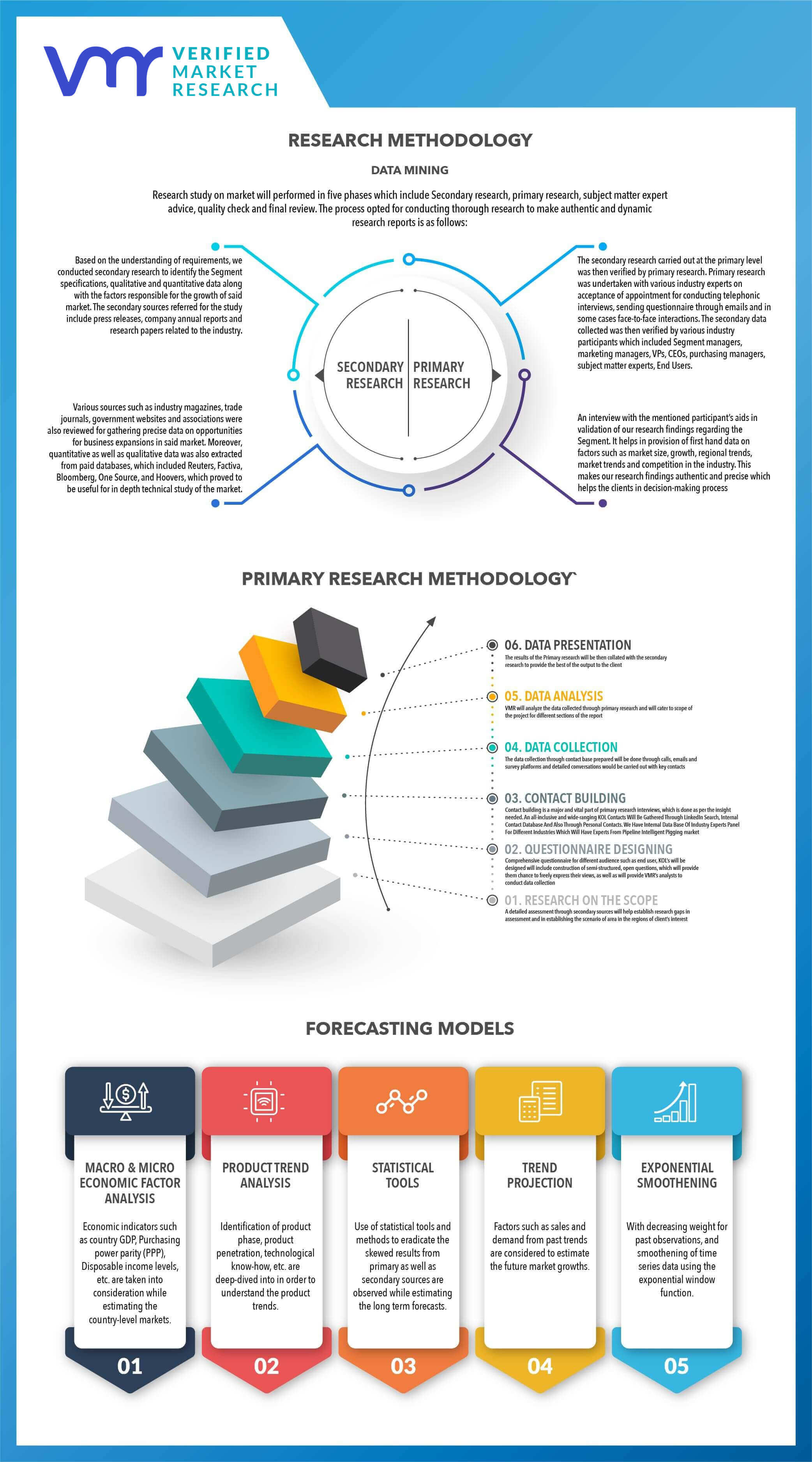

Research Methodology of Verified Market Research

To know more about the Research Methodology and other aspects of the research study, kindly get in touch with our Sales Team at Verified Market Research.

Reasons to Purchase this Report:

• Qualitative and quantitative analysis of the market based on segmentation involving both economic as well as non-economic factors

• Provision of market value (USD Billion) data for each segment and sub-segment

• Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

• Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

• Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions and acquisitions in the past five years of companies profiled

• Extensive company profiles comprising of company overview, company insights, product benchmarking and SWOT analysis for the major market players

• The current as well as the future market outlook of the industry with respect to recent developments (which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

• Includes an in-depth analysis of the market of various perspectives through Porter’s five forces analysis

• Provides insight into the market through Value Chain

• Market dynamics scenario, along with growth opportunities of the market in the years to come

• 6-month post-sales analyst support

Customization of the Report

• In case of any Queries or Customization Requirements please connect with our sales team, who will ensure that your requirements are met.

Frequently Asked Questions

The post Global Cutting Fluid For Semiconductor Equipment Manufacturing Market Size By Type (Cooling, Lubrication), By Application (Drilling And Milling, Grinding And Polishing), By Cutting Fluid Type (Synthetic, Semi-Synthetic), By Geographic Scope And Forecast appeared first on Verified Market Research.